Get moving with Mainline Full Floating Hose.

Mainline Full Floating HoseMain Carcass:

Mainline Full Floating Hose Floatation:

Mainline Full Floating Hose Outer Cover:

Mainline Full Floating Hose Fittings: End connections built in during manufacture. ASME B 16.5 Class 150lb or 300lb Weld Neck Flat Face or Raised Face on request.

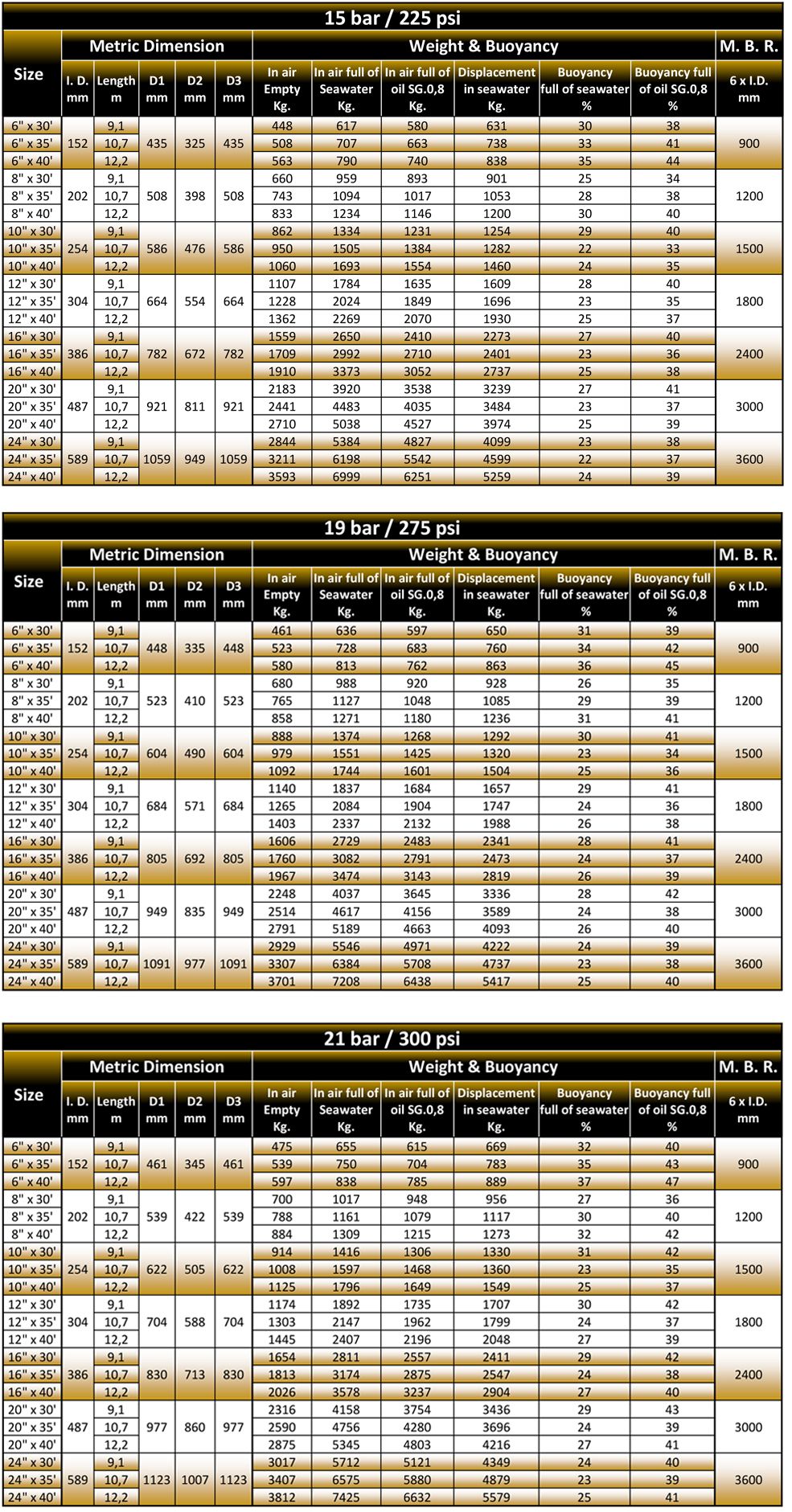

Mainline Full Floating Hose Tests: All tests according to GMPHOM 2009 and Customer detail.

Mainline Full Floating Hose Application:

The floating marine oil hose is designed for transportation of crude oil and liquid petroleum products between loading and unloading vessels at offshore mooring systems.

Mainline Full Floating Hose Characteristic:

Mainline Full Floating Hose Standard:

The floating oil marine hoses are designed and produced in full accordance to OCIMF standard,the marine hoses are subjected to manufacturing and testing requirements dictated by ISO9000 quality standards.

We will contact you within 1 working day, please pay attention to the email with the suffix “@pipelines.com.cn”.

Join our newsletter to the latest news, updates, and special offers!!